Frequently Asked Questions

Browse our ever expanding mindmap of Integra Adhesives questions, tips and tricks, and more.

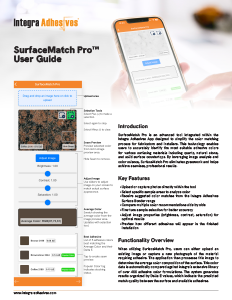

SurfaceMatch Pro™ – Key Features

- Upload or capture photos directly within the tool

- Select specific sample areas to analyze color

- Receive suggested color matches from the Integra Adhesives Surface Bonder range

- Compare multiple color recommendations side-by-side

- Fine-tune sample selection for better accuracy

- Adjust image properties (brightness, contrast, saturation) for optimal results

- Preview how different adhesives will appear in the finished installation

Download brochure for more information.

Why More Fabricators are Switching to Integra Cartridge Adhesive

- Save Time on the Jobsite

- Minimal Surface Preparation

- Consistent Color

- Perfect Mix Ratio

- Superior Chemistry

- Zero Callbacks

Benefits of Cartridge Adhesive vs. Bulk Adhesive

- Perfect color match

- Consistent ratio, color

- Ready to apply

- Smooth application

- Clean, easy application

- Minimal product waste

- Tidy, fast clean-up

- User friendly

Will your adhesive work on Corian™?

Yes. Our Surface Bonder SSA is formulated to provide the strongest bonds on the largest selection of materials. It can be used on all the major brands of Solid Surface:

- Acrylic,

- ISO-NPG Polyester,

- Ortho Polyester, and

- Acrylic-Polyester alloys.

For a complete list of surfaces covered see our Colour Charts. If you don’t find what you are looking for – contact us – we strive to keep up with new colours and products and may have already matched it.

Will your adhesives work on Engineered Stone, Porcelain/Ceramic and Granite?

Our Surface Bonder SSA, Surface Bonder ZERO, and Surface Bonder Rapid are all designed to work on all Engineered surfacing materials, Porcelain/Ceramics and Natural Stone. The colours were developed to match. It’s recommended to use Surface Bonder ZERO, and Surface Bonder Rapid for hard surfaces like Porcelain and Natural Stone.

- Cambria®

- Caesarstone®

- LX VIATERA

- Silestone®

- MSI Q™ Quartz

- Corian® Quartz

- Wilsonart® Quartz

- PentalQuartz®

- Daltile ONE Quartz®

- Neolith®

- Dekton®

- Laminam®

- and many more on our colour charts

The wide range of colour options also makes these adhesives an excellent choice for Granite and Natural Stone Fabrication. Watch our videos or contact Integra for advice on fabrication with your surfacing material.

What's the difference between Surface Bonder SSA, Surface Bonder ZERO and Surface Bonder Rapid?

While all three of these products are designed for seamless colour matching on a multitude of surfaces, each have properties that make them more suitable for certain materials.

Surface Bonder SSA (or Solid Surface Adhesive) was developed with Solid Surface fabrication and installation in mind. Its unique formula was designed to bond with acrylic resins, and match the refractive index allowing for seamless colour matches.

Surface Bonder ZERO and Surface Bonder Rapid were designed for use on hard surfaces. Their formulas allow them to penetrate into porous surfaces and using their high shear strength they can bite onto microscopic ridges and perforations in the material to further increase their mechanical bond strength.

Where can I buy your products?

Integra Adhesives product range is available all across Europe. If you can’t find anyone in your area on our distributors page, we can help you to find someone that can ship to you via our contact us page. Most companies offer shipping times in as little as 1-2 business days.

How strong are your adhesives?

Each of our adhesives have different bond strengths for various surfaces and applications. The table table below should provide you with a starting point on some of our products.

Additional information can be found on our documentation page or each individual product page.

| Adhesive | Strength Test | Surface | Characteristic |

|---|---|---|---|

| Surface Bonder SSA | Flexural | Solid Surface | 27–41 MPa (N/mm²) / Substrate Failure |

| Surface Bonder SSA | Flexural | Quartz / Mineral | 20–27 MPa (N/mm²) / Substrate Failure |

| Surface Bonder ZERO | Flexural | Compact Sintered/Porcelain/Ceramic | >27 MPa (N/mm²) / Substrate Failure |

| Surface Bonder ZERO | Flexural | Natural Stone | >27 MPa (N/mm²) / Substrate Failure |

| Surface Bonder ZERO | Flexural | Quartz / Mineral | >27 MPa (N/mm²) / Substrate Failure |

| Surface Bonder Rapid | Flexural | Natural Stone | >27 / MPa (N/mm2) |

| Surface Bonder Rapid | Flexural | Quartz / Mineral | >27 / MPa (N/mm2) |

| Surface Bonder Rapid | Flexural | Compact Sintered/Porcelain/Ceramic | >27 / MPa (N/mm2) |

| Construction Bonder | Lap Shear | Acrylic Solid Surface | 17-20 MPa (N/mm2) |

| Construction Bonder | Lap Shear | Polyester Solid Surface | 17-20 MPa (N/mm2) |

| Construction Bonder | Lap Shear | Steel/Stainless Steel | 19-24 MPa (N/mm2) |

| Construction Bonder | Lap Shear | Aluminum | 13-17 MPa (N/mm2) |

How can I get a countertop matched that's not on your website/app?

We’re more than happy to match anything you send our way. Contact us to get in touch with our colour match technicians. This process can take time depending on backlog, so let us know the urgency of your request and we’ll try to have it ready as soon as possible.